Circular Economy

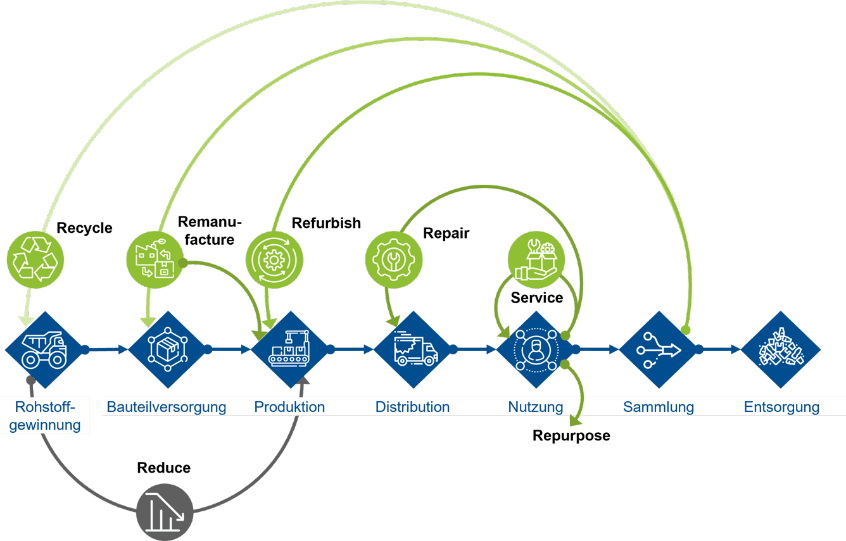

The manufacturing industry’s answer to sustainability is the circular economy along its own value chain. Our experience confirms that the fastest and most effective way to a more sustainable and yet economical enterprise is based on the circular economy. In this way, you can derive sustainable economic benefits from consistently ecological action. To do this, it is necessary to consider the model throughout product life cycle. We are happy to assist you in this transformation.

Why TMG Consultants?

For Your Sustainable Circular Economy

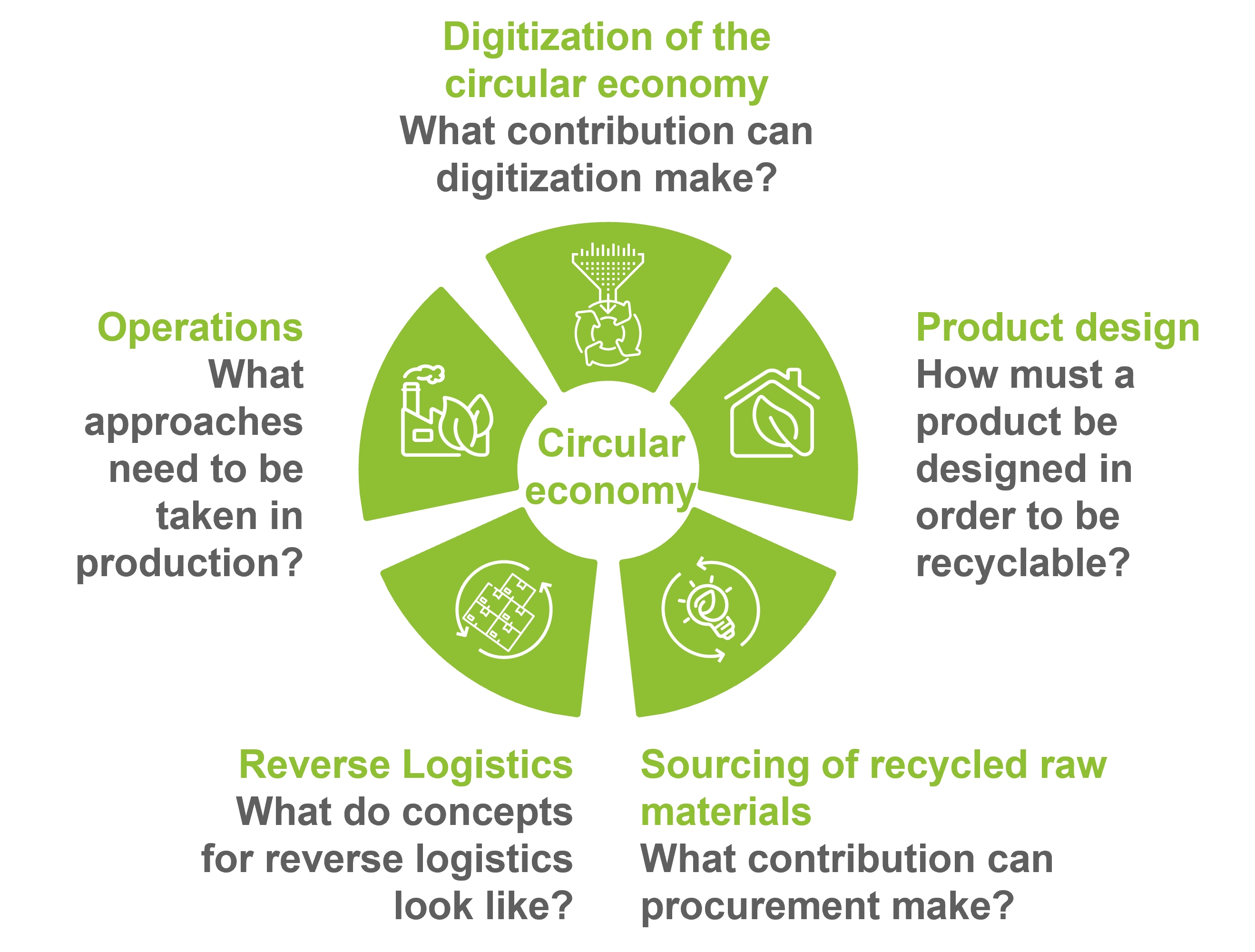

We draw on experience from numerous consulting projects as well as expert knowledge to support you in five essential areas on the way to the Circular Economy.

Circular economy requires recyclable products

Product design

- How do products need to be designed to survive in a circular economy model?

- What conflicts of interest arise with the current orientation of product design?

- What adjustments does this require in product development and product strategy?

- What success criteria need to be observed in the development of products?

- In which areas do companies need to build up competence?

The foundation of recyclable products

Procurement

- What contribution can procurement make in the context of the circular economy?

- How sensible is it to increasingly use recycled materials in the future?

- What are the particularities of secondary raw materials and recyclable materials?

- How can suppliers be found in the short term who have suitable recyclates in their range and can be considered as partners?

- How can artificial intelligence be used to find the right suppliers?

Basic prerequisite for re-manufacturing processes

Reverse Logistics

- Why is reverse logistics so important in the Circular Economy?

- What distinguishes it from normal logistics?

- What success factors need to be considered when setting up reverse logistics?

- Which types of reverse logistics are suitable for which circular economy model?

- How can optimal reverse logistics be set up?

Production processes as the key to sustainability

Operations

- What role does production play in the context of the circular economy?

- What possibilities and concepts apply for production to design and establish closed material cycles?

- Which strategic questions do companies have to answer to approach the circular economy in a well-founded way?

- What preconditions need to be created to make the circular economy possible?

- What stumbling blocks and success factors need to be taken into account?

The enabler for a successful circular economic model

Digitalisation

- What role does digitalisation play in the Circular Economy?

- Which challenges of the Circular Economy require a stronger focus on digital solutions?

- What potential does digitalisation offer manufacturing companies on their way to the Circular Economy?

- Which digital solutions are suitable as enablers for the Circular Economy and which use cases are conceivable?

- What added value does a specially adapted PLM deliver in a circular economy model?

Increased sustainability in the materials cycle

Zero Waste Economy

We draw on experience from numerous consulting projects as well as expert knowledge to support you in five essential areas on the way to the Circular Economy.

If a large proportion of materials, products and raw materials remains in the materials cycle for as long as possible and only a minimal proportion is disposed of as waste, this not only has a positive effect on waste flows. The demand for primary raw materials can also be massively reduced if materials are reused and returned to the resource cycle as secondary raw materials. The theoretical ideal of this school of thought is the zero waste economy – a circular economy in which neither new raw materials need to be mined nor waste disposed of.

Contactform

We look forward to talking to you!

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information